July 22, 2018

July 22, 2018

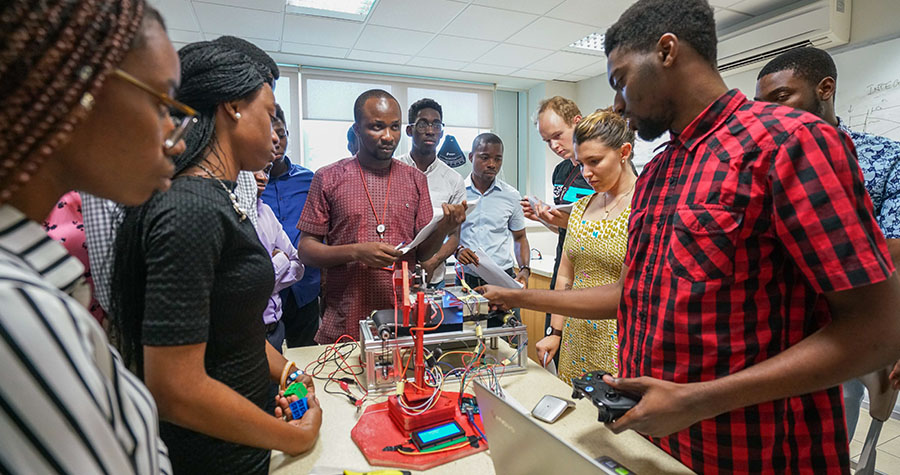

Robotic arms sorting and picking colored bricks off conveyor belts is not a sight you see every day at Ashesi. However, following a six-week Introduction to Engineering course, first-year Engineering students designed and built automated factory setups that did just that.

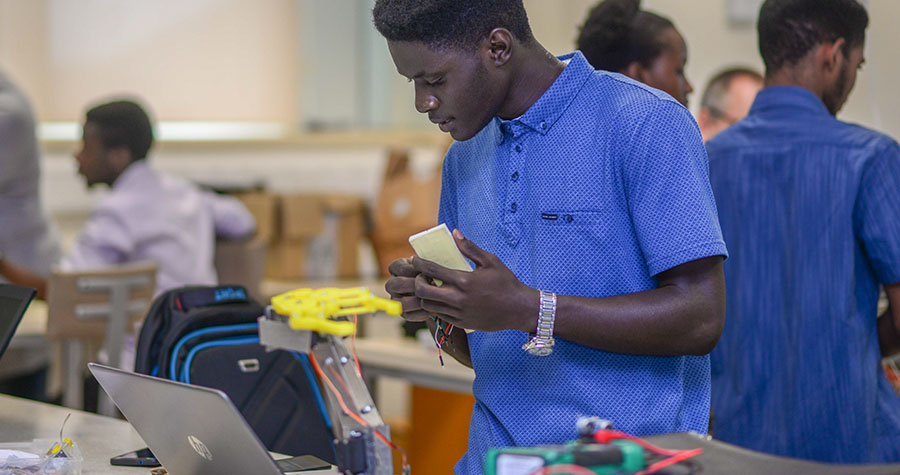

As part of the course, the students explored 3D modeling, programming, designing, and construction, as key tools for building solutions to problems.

“In factories, you’ll find that the conveyor belt is a very important part of the full set-up; helping to transfer items from one place to another,” said Nicholas Tali, Engineering Lab Manager. “Today, robots play just as important a role in factories as well, so the idea of this exercise was for the students to gain a sense of how they can build these two elements to work together. The project also pushed them to use a wide array of tools, equipment, and knowledge, thereby exposing them to the various engineering disciplines and how they can come together to form one working system.”

Over the long break at Ashesi, through the Introduction to Engineering course, first-year Engineering students explore how they can use tools to address or contribute to societal gaps.

In 2017, the Ghanaian government launched an initiative to establish a factory in every district in Ghana to help improve industrialization across the country. This year’s project was structured around this initiative, allowing the students to contribute to the national initiative.

“Implementing projects that directly impact national agenda helps inform the students of what’s going on in their community,” said Tali. “This year’s project was designed to help them gain an appreciation of efficient factory setups.”

For the students, the experience not only was an introduction to Engineering in practice but also, it helped them gain a sense of the reality of work in the real world.

“Besides learning to use the various tools and machines in the project, I also learned that engineering is more than just proudly declaring that you’re an engineer,” said Tamisha Segbefia ’21. “The most important lesson I took from this experience is that, even in the real world, things can and do sometimes fail. For my team in particular, our code suddenly stopped working the night before the final exhibition, and we ended up re-doing our entire set-up. All in all, it was a fun experience because we learned more about teamwork than we had in a long while. Even though it was stressful, we learned that it’s good to persevere even when things fail.”

Share this story