October 8, 2017

October 8, 2017

Over the long break, some of our engineers explored the real world; taking on everyday and complex problems in various insternships and projects.

From installing fuel pumps to helping to set up Ashesi’s solar plant to fabricating low-cost fruit grinders for underserved communities, here they share their experiences, impact made and lessons learned.

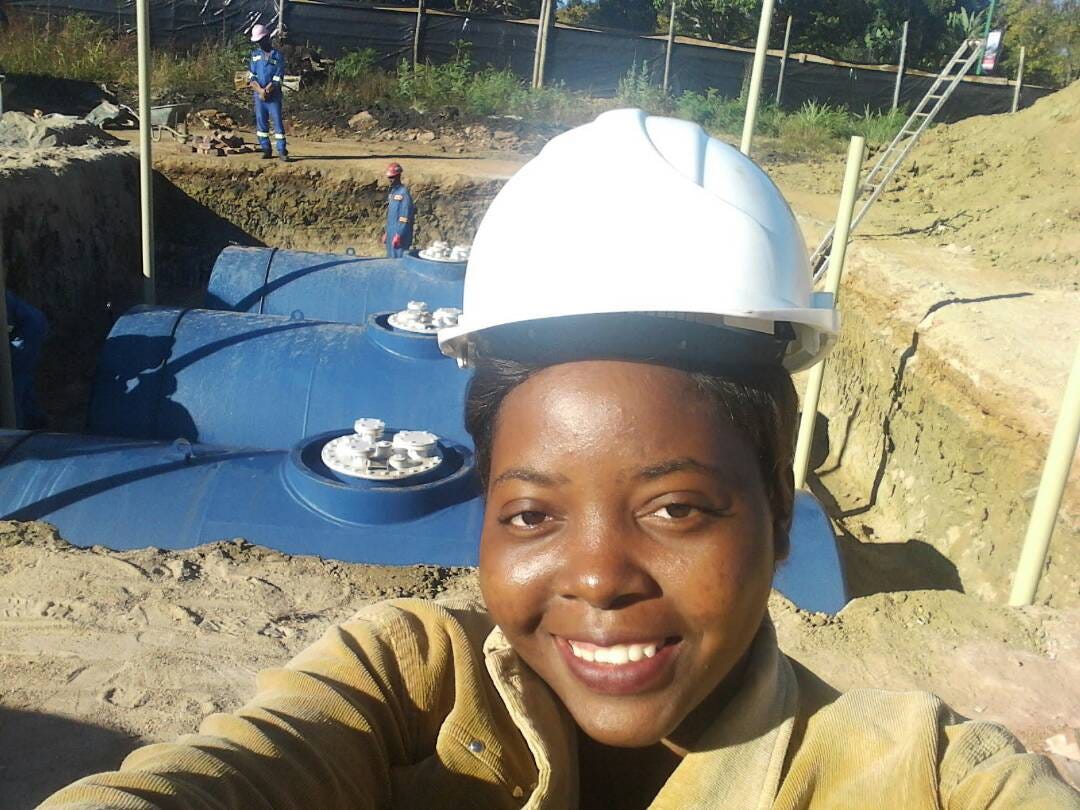

Jenipher Panashe ‘18, Fueltec, Harare Zimbabwe

For three months, I was the assistant projects engineer at Fueltec, a Southern African firm that deals in the designing, installation and construction of gas installations on commercial scale. In my role, I assisted the Projects Engineer as assigned with research, development, test and actual design of Fueltec products and services. Primarily, I learnt how to design a service station, preparing Bill of Quantities(BOQ) and drafting quotations for customers.

I didn’t really face so much challenges besides the fact that I was the only female in my department. Being the only female meant that I had to up my game a little bit. Usually, the technicians were the ones who did service jobs. I used to go for service jobs three days a week and then the other 2 days I would work on design and paper work like quotations. However, the Technicians were usually a bit hesitant to allow me to use spanners, do heavy work or for me to get my hands dirty since I was a woman. Therefore, I had to take the initiative and say I can do it also. Once they realized I was eager to learn and work, I got more practical work to do.

Through my experience, I found lessons from my Circuits and Electronics class especially helpful, in the installation and repairing of petrol pumps. Also, my SolidWorks (Introduction to Engineering Class) came in handy. In designing the service stations, we used AutoCAD, a similar tool to SolidWorks. In addition, the Career Services sessions I had throughout my 2 years were helpful particularly the MCF Summer Program. I had the ability to communicate and relate well with other employees.

Having real industry experience is a necessity for all engineers. My internship has helped me to see engineering in a whole new light. This semester, it’s amazing to realize that the lessons I learnt during my internship are what we are learning now in class. Unlike the previous semesters, I am now excited to learn the theory aspect of engineering since I have had a taste of what ‘real engineering’ is about.

PS: I also got my hands dirty, holding spanners, grease, hammers, getting in manholes, climbing petrol trucks and a whole lot more.

Kofi Anweara ‘18, Burro, Koforidua, Ghana

Before senior high school, to help my family make ends meet, I joined the illegal mining trade, popularly known as galamsay. Here I started getting used to machines and how they worked. After senior high school, I worked for a water-bagging company, managing machinery in the factory. While these experienced were unconventional and risky, I built my experience in learning the mechanics of machinery.

This long break, I spent three months in Koforidua working with Burro, to find solutions for underserved communities.

As a company Burro’s mission is to serve underserved communities by providing them solutions to their everyday challenges. To do this, they usually go to village to interact with the people to plug into their daily lives, understand the kinds of problems people are facing and try to come up with solutions to fill those gaps. In one of such villages, we took on the oil palm industry, identifying, the pounding process as a pain point in palm oil processing.

For this, my task was to design and build a machine that would address this pain point. So, I built a prototype of what we called, a palm oil digester, a machine that helped “pound” the palm nuts. So after building, we take it to our end-users to test the products and give us feedback.

I also got the opportunity to go to my hometown up North for the first time, we explored the trying to eliminate pain points from the shea-nut industry as well.

Finally we explored the cocoa industry, where we tried to find effective ways of drying the beans, trashing and also implementing security setups to protect the farmers.

From my internship experience, initially when I have an idea in my hide, taking it out from the abstract into reality was a struggle, but over there, I learnt to properly work in bits, building small prototypes of my idea. I learnt to start from something small and learn to scale up.

Working at Burro, I had the freedom to focus on work. Once the goal is set, you work towards it. When I got there, and was given my task, I was given total freedom to get work done. That sort of freedom gave me the chance to work precisely on what I was interested in.

While I’m an electrical engineering major, my internship experience largely focused on mechanical engineering, and for me it was a blessing.

The things I don’t know I consider are the next important step for me, and I don’t bother about what I already know, or will have the privilege of gaining experience in. In this way, I can build my experience in other areas beyond electrical.

Jacob Nii Sackey Vanderpuye ‘18, Justice Valentine Essuman ‘18, Victor Hazel ‘18

The trio spent their long break working with Azimuth Power who have partnered with Ashesi as part of the institution’s move to solar energy. As part of their work, they installed inverters for the solar panels, performed string calculations for the panels, did cabling, calculating trusses for the roofs and covered the full spectrum of activities involved in the solar installation process.

The team also built a hoist to help lift the panels up onto the roof.

Jacob Nii Sackey Vanderpuye

This experience allowed me to discovered a new passion in renewable energy. As it’s a relatively unexplored sector in the country, when I heard about the solar project going at Ashesi, I joined.

I came on-board this project seeing the potential it has to impact the entire energy structure in Ghana, and for me it’s a step in the right direction. We want future generations to come to Ashesi and experience a clean environment, and this project takes us a step closer to this goal.

When you’re an engineer, you look to a job being reliable, efficient and cost-effective, and this experience has these qualities.

Victor Hazel

It was very helpful to have hands-on experience, from making sketches for the inverters to working on the field with the technicians. I realized doing designs on the computer can be totally different from execution on site.

I’m a risk taker, and I look for opportunities everywhere. So when I heard about this project, I realized I hadn’t had any industry experience, so I figured this would be a good place to build experience.

Realising Azimuth is also new Ghana, I realised it would be great to learn from them, and be part of their growth. One thing I learnt is to pay attention to detail.

The experience influenced the way I look at things. I learn how to manage people, how to manage projects .

Justice Essuman

The whole energy sector in Ghana, should probably be looking at this direction, where we can harness several of the free resources we have.

While this re-orients the university’s direction into conserving energy, it also sets a mark for other institutions to follow.

It makes sense for our continent to move into solar, if Africa looks to welcoming the future. With the skills I’ve acquired, I’ve been placed in the right position to think about starting a solar start-up soon.

Dzifa Hodey ‘19

Rounding-off their first year, the freshman Engineering class for their final project for the year, designed and built solar powered smart irrigation systems. The project was part of the six-week long Introduction to Engineering class, where the students are introduced to a breadth of tools and equipment to help break them into the Engineering field.

For Dzifa Hodey, this experience helped her understand better, what engineering entails.

I knew I wanted to major in electrical engineering but I started having second thoughts. Since I was exposed to all the engineering fields during the summer course, I became clear in mind concerning my major

Working in a team, I realised working alone may not be effective because you need knowledge from other people. It’s also important to have knowledge of several fields. For instance, we handled plumbing, electricals and mechanical parts even though I’m majoring in electrical and electronics engineering

In the end, I was motivated in the sense that I have the ability to take a stab at coming up with working solutions that can solve some of African’s problems.

See video of the project here: https://www.facebook.com/Ashesi/videos/1540131156030067/

Share this story