As we celebrate the graduating class of 2023, we take a look at some of the stories and work of the students in the class. Follow the highlights on social media using #Ashesi2023 and #AshesiGrad.

In Summary

- Students Daniel Amoshie and Munashe Nyazenga leveraged black soldier flies for affordable fertiliser and animal feed in their small-scale farming projects during COVID-19 lockdowns.

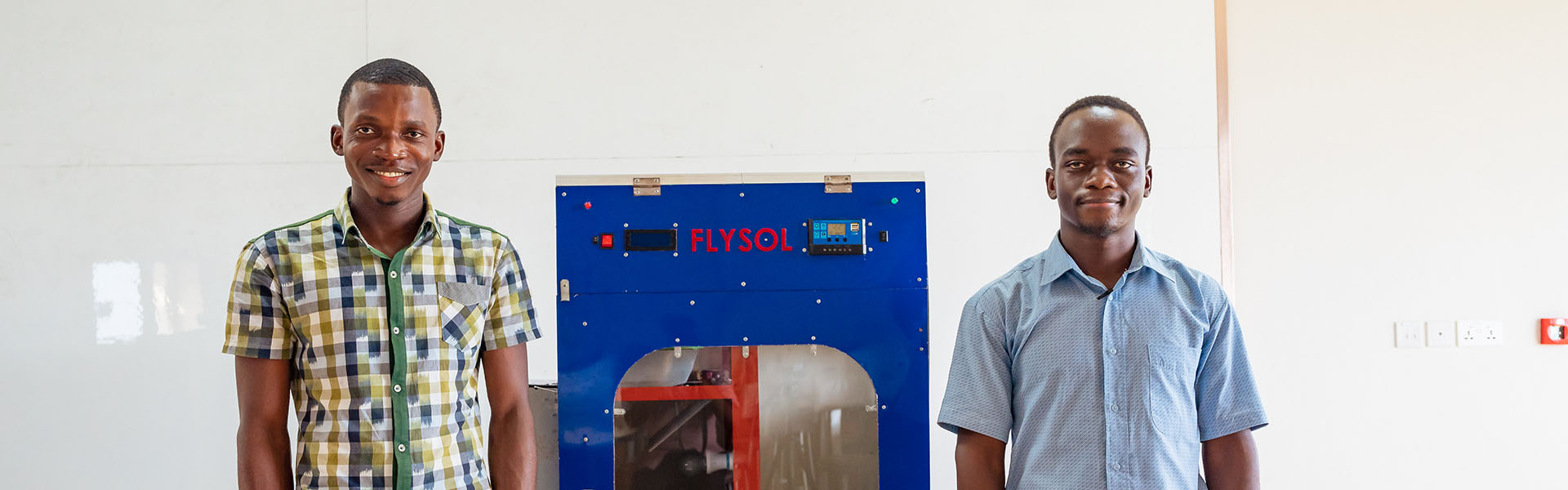

- They developed “Flysol,” an automated breeding machine for managing the lifecycle of these insects, for their final-year Engineering project after they realised how difficult it was to breed them. Flysol addresses high farming costs and repurposes food waste, offering a sustainable solution for future farming needs.

- This project was supervised by faculty member Dr. Elena Rosca. For more information, visit the project site: Flysol.

Go further

Daniel Amoshie ’23 and Munashe Nyazenga ’23 have long held a keen interest in farming. During the COVID-19 lockdowns, their passions blossomed into enterprises, with Munashe establishing a sugar bean farm in Zimbabwe, supported by the Mastercard Foundation Entrepreneurs Fund. At the same time, Daniel started a small catfish farm in Ghana. However, they soon faced similar challenges – Munashe was searching for affordable fertiliser to boost soil fertility, and Daniel grappled with the high cost of traditional protein feed for his fish.

In their quest for solutions, the two engineering students stumbled upon an innovative yet unconventional resource – black soldier flies. Comprised of up to 60% protein, these insects offered a cost-effective alternative – with their nutrient-rich larvae able to break food waste into compost or directly processed for animal feed. However, they soon discovered that managing the lifecycle of the insects – which were highly sensitive to environmental conditions – presented its own difficulties.

To overcome this, the two united their efforts for their final-year engineering project, focusing on building an automated breeding machine for black soldier flies.

“Black soldier flies are remarkable insects with the unique ability to break down organic waste quickly and efficiently,” says Daniel. “We built our device to simplify the management and control of the rearing process, allowing for the consistent production of high-quality protein feed and fertiliser for small to medium-scale farmers.”

Their resulting product, “Flysol,” features a working incubator prototype that integrates computer vision, temperature control, and feeding systems to regulate and monitor conditions for the larvae to thrive. With remote alerts and a live video feed accessible via a mobile phone or web dashboard, farmers are offered the tools for efficient and optimal production.

Smallholder farmers produce an estimated 70% of Africa’s food, but many struggle with low crop yields due to poor soil health and traditional farming practices. Many are also unable to afford more sustainable organic fertilisers.

“The escalating costs of feed and fertiliser make it increasingly challenging for farmers to sustainably produce enough food to meet the demands of the world’s growing population,” adds Munashe. “Also, a significant portion of food waste isn’t being put to good use. Flysol addresses both these issues.”

“It wasn’t easy finding the right data to train our system to be adaptive,” Daniel confesses.”Sourcing components locally was also a significant hurdle. Thankfully, we found a way forward with the support from our department and our supervisor, Dr Elena Rosca.”

Share this story